Stainless Steel Winding Strip

- Home

- Stainless Steel Winding Strip

Stainless Steel Winding Strip

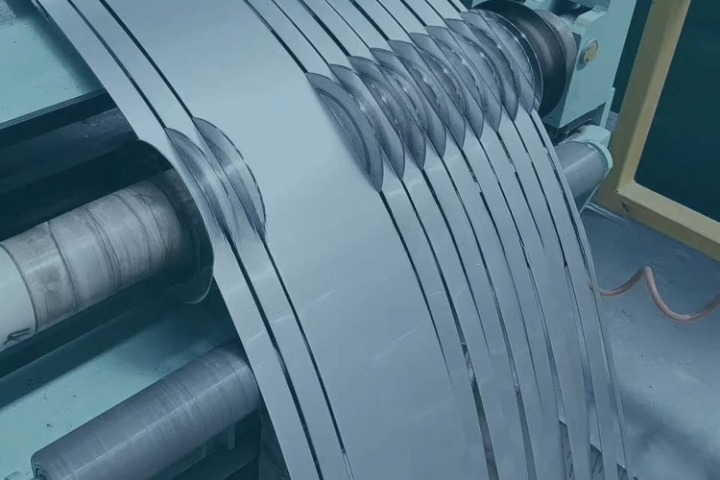

Stainless steel winding strips are popular for their durability, versatility and widespread use across settings. They boast resistance to corrosion, strength and a pleasing aesthetic. Thin and flat pieces of steel these strips are expertly wound or coiled for specific applications in different industries.

A standout feature of stainless steel winding strips is their ability to resist rust and corrosion making them perfect for environments exposed to moisture, chemicals or harsh conditions. Whether utilized in structures, machinery or chemical plants these strips offer reliable performance over the long term.

Beyond their corrosion resistance stainless steel winding strips are renowned for their strength to weight ratio. This attribute makes them ideal for applications requiring integrity like elements, automotive components and electrical casings. The ease with which stainless steel can be shaped, cut and welded to meet specifications is valued by manufacturers; this adaptability makes these strips cost solutions for diverse projects.

Furthermore the aesthetic appeal of stainless steel winding strips adds to their value. The sleek and shiny surface of steel gives an tidy look to final goods enhancing their visual charm for architectural features, interior design elements and ornamental trim parts.

From heavy duty machinery to household devices stainless steel coiling strips play a role as components that enhance the dependability and functionality of a wide array of products. Their sturdy build, flexibility and pleasing appearance make them a sought after material in sectors where top notch quality and performance are crucial.

Stainless steel coiling strips are materials in applications providing a blend of durability, resistance to corrosion and aesthetic appeal that positions them as the preferred option for manufacturers and designers across different fields.

Stainless Steel 304/304l/304h Winding Strip Specification

| Item | Stainless Steel 304/304l/304h Winding Strip (Hot rolled, cold rolled) | |

| Thickness | 0.18 mm 0.2 and as per Customer Requirement | |

| Size | 3,3.2, 3.5, 3.6, 3.8, 4.5,4.57,4.8,5,5.2,5.5, 7.2 mm and as per Customer Requirement | |

| Width | 3 mm to 2000 mm and as per Customer Requirement | |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc | |

| Standard | JIS, AISI, ASTM, GB, DIN, EN, etc | |

| Surface |

2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc |

|

| Brand: | Indian Origin, European Origin, Japanese Origin, US Origin, Korea Origin, Thailand Origin, Taiwan Origin |

|

| Manufacturer: | POSCO, Aperam, Jindal Stainless, DKC Korea, Thyssenkrup, Baosteel, TISCO, Arcelor Mittal, VDM, Nippon Metal, Outokumpu |

|

| Package | Shrink-wrapped ,Carton boxes,Wooden pallets,Wooden boxes ,Wooden crates Etc. required. |

|

| Export to | India,

Indonesia,

Malaysia,

Singapore,

Saudi Arabia,

Qatar,

UAE,

Iran,

Iraq,

Oman,

South Africa, Nigeria, Kenya, Italy, UK, Brazil, Russia , Egypt , Kuwait , Taiwan, Australia . |

Stainless Steel 304/304l/304h Winding Strip Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | 3304S11 | 03Х18Н11 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 |

| SS 304H | 1.4948 | S30409 | - | - | - | - | - |

Chemical Properties Of 304/304l/304h Stainless Steel Winding Strip:

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | - | 8 – 11 | - |

| SS 304L | 0.035 max | 2 max | 1.0 max | 0.045 max | 0.03 max | 18 – 20 | - | 8 – 13 | - |

| SS 304H | 0.10 max | 2 max | 0.75 max | 0.045 max | 0.03 max | 18 – 20 | - | 8 – 10.5 | - |

304/304l/304h Stainless Steel Winding Strip Application

- 304/304l/304h Stainless Steel Winding Strip Used in Tractor

- 304/304l/304h Stainless Steel Winding Strip Used in Automotive Trim

- 304/304l/304h Stainless Steel Winding Strip Used in Stamped Machined Products

- 304/304l/304h Stainless Steel Winding Strip Used in Cookware

- 304/304l/304h Stainless Steel Winding Strip Used in Appliances

- 304/304l/304h Stainless Steel Winding Strip Used in Kitchen

- 304/304l/304h Stainless Steel Winding Strip Used in Foodservice Equipment

- 304/304l/304h Stainless Steel Winding Strip Used in Sinks

- 304/304l/304h Stainless Steel Winding Strip Used in Railway Cars

- 304/304l/304h Stainless Steel Winding Strip Used in Trailers

304/304l/304h Stainless Steel Winding Strip Processing

The majority of normal processing can be performed on 304/304l/304h Stainless Steel Winding Strip Jainex Steel & Metal Offers Following Processing for 304/304l/304h Stainless Steel Winding Strip:

- 304/304l/304h Stainless Steel Winding Strip Testing

- 304/304l/304h Stainless Steel Winding Strip Cutting

- 304/304l/304h Stainless Steel Winding Strip Grinding

- 304/304l/304h Stainless Steel Winding Strip Forming Drilling/ Machining

Packaging:

We Jainex steel & Metal Ensure the best quality of Packing , because its play important role especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put extraordinary concern regarding packaging.

We pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as:--

- • Boxes and Crates

- • Shrink-wrapped

- • Carton boxes

- • Wooden pallets

- • Wooden boxes

- • Wooden crates

Testings (Destructive, Non Destructive):

- • Positive Material Identification - PMI Testing

- • Chemical Analysis - Spectro Analysis

- • Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- • Micro Test

- • Macro Test

- • Hardness Test

- • Pitting Resistance Test

- • Intergranular Corrosion (IGC) Test

- • Flaring Test

- • Flattening Test

- • Hydrostatic Test

- • Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- • Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- • Radiography Test

- • Dye Penetrant Test (DP Test)

- • Ultra Sonic Test (UT)

- • Eddy Current Testing

- • Impact Test

- • Bend Test

Stainless Steel 304/304l/304h Winding Strip Supplier

Jamshedpur, Rajkot, Lahore, Geoje-si, Jakarta, Kolkata, Gimhae-si, Vung Tau, Karachi, Istanbul, Manama, Kuwait City, New Delhi, Calgary, Ranchi, Muscat, Hyderabad, Mumbai, Moscow, Kuala Lumpur, Nashik, Busan, Ho Chi Minh City, Singapore, Aberdeen, Algiers, Cairo, Chandigarh, Bangkok, Indore, Rio de Janeiro, Montreal, Al Khobar, Riyadh, London, Baroda, Granada, Ankara, Ahvaz, Port-of-Spain, Caracas, Vadodara, Sydney, Thiruvananthapuram, Lagos, Pimpri-Chinchwad, Ernakulam, Nagpur, Coimbatore, Mexico City, Santiago, Abu Dhabi, Dammam, Surat, Ludhiana, Bogota, Courbevoie, Dallas, Milan, Ahmedabad, Houston, Ulsan, Visakhapatnam, Colombo, New York, Chennai, Toronto, Melbourne, Noida, Tehran, Perth, Bengaluru, Brisbane, Petaling Jaya, Jaipur, Navi Mumbai, Atyrau, Jeddah, Secunderabad, Kanpur, Gurgaon, Howrah, Hanoi, Hong Kong, Haryana, Edmonton, Los Angeles, Faridabad, Seoul, Madrid, Sharjah, Bhopal, Thane, La Victoria, Pune, Dubai, Chiyoda, Doha, Al Jubail

304/304l/304h Stainless Steel Winding Strip Exporter

India, Brazil,Hong Kong,Switzerland, Singapore, Australia, Costa Rica, South Korea,Japan, Tibet, Nigeria, Angola, Sri Lanka, Libya, Mexico, Kuwait, Bhutan, Bulgaria, Nepal, China, Kenya, Croatia, Sweden, Trinidad & Tobago,Tunisia, Egypt, France, Bolivia, Peru, Mexico, United Kingdom, Austria, Portugal, New Zealand, Belgium, Taiwan, Poland, Macau, Israel, Serbia, Malaysia, Germany, Venezuela, Afghanistan, Ireland,

South Africa, Azerbaijan, Oman, Belarus, Gambia, Saudi Arabia, Ukraine, Morocco, Greece, Spain, United Arab Emirates, Jordan, Ecuador, Nigeria, Chile, Czech Republic, Philippines, Iran, Chile, Netherlands, Canada, Namibia, Norway, Puerto Rico, Yemen, Romania, Mongolia, Slovakia, Kazakhstan, Ghana, Turkey, Finland, Lithuania, Italy, Qatar, Colombia, Russia, Lebanon, Indonesia, Bangladesh, Zimbabwe, Poland, Thailand, Gabon, Pakistan, United States, Iraq, Iran, Bahrain, Algeria, Argentina, Hungary, Denmark, Estonia, Vietnam